I-Carbon fiber prepreg iyimpahla eluhlaza yokucubungula ibhodi le-carbon fiber.Ngosayizi wayo wokudonsa, ingahlukaniswa ibe ngu-1k, 3k, 6k, 12k, njll., ngokuvamile 3k isetshenziswa kakhulu.I-Jiangsu Boshi Carbon Fiber izophinde icubungule ingaphezulu lebhodi le-carbon fibre ngokwezidingo zamakhasimende, njenge-plain/twill, bright/matte, kanye nokuqoshwa ngokwezidingo esikhathini sakamuva.Inqubo yokukhiqiza yebhodi le-carbon fiber ihlanganisa ukusika, ukubeka, ukuphulukisa, ukusika kanye nokucubungula ngemuva kwe-carbon fiber prepreg.

1. Ukuthungwa kwe-prepreg:

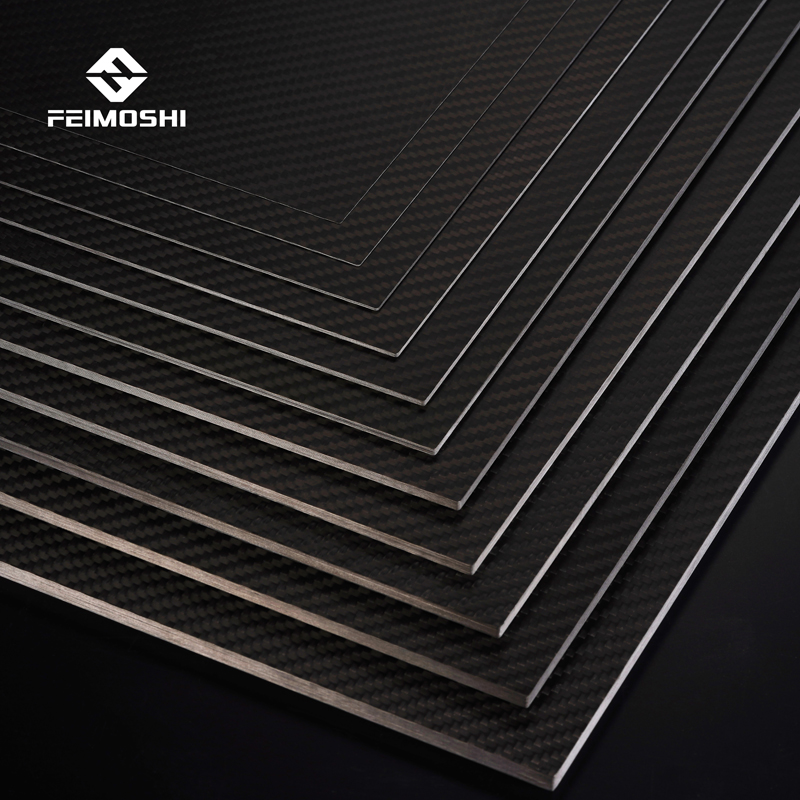

Okokuqala, sidinga ukusika i-prepreg ngokuya ngobude nobubanzi beshidi le-carbon fibre, futhi sinqume ubukhulu obudingekayo be-prepreg ngokusho kobukhulu beshidi.I-Jiangsu Boshi Carbon Fiber ineminyaka eminingi yesipiliyoni esicebile ekukhiqizeni amabhodi e-carbon fiber.Amabhodi e-Carbon fibre enobukhulu obuhlukahlukene angenziwa ngokwezifiso ngokuya ngezidingo zamakhasimende.Ubukhulu bebhodi obujwayelekile yilawa: 0.2mm, 0.5mm, 1.0mm, 1.5mm, 2.0mm, 3.0mm, 5.0mm, 6.0mm, 10.0mm, 20mm, njll.

Uma ishidi lijiyile, kudingeka izendlalelo ezengeziwe ze-carbon fibre prepreg.Ngokuvamile, ibhodi le-carbon fiber engu-1mm lidinga izendlalelo ezingaba ngu-5 ze-prepreg.U-Boshi wethule umshini wokusika ozenzakalelayo ongenisiwe ukuze usike i-prepreg, engalawula kangcono usayizi nekhwalithi yokusika.Abaqambi be-Boshi bazothuthukisa idizayini ngaphambi kokusika, okungakhuphula izinga lokusetshenziswa kwe-prepreg futhi kunciphise ukukhiqizwa kwamamajini, ngaleyo ndlela kusize amakhasimende ehlise izindleko zokukhiqiza.

2. Ukubekwa kwangaphambi kokukhulelwa:

Umehluko wokulandelana kwe-layup ngeke nje uthinte umthwalo wokuqala, izinga lokukhula, nokuqina kokuphuka kwemifantu ye-matrix, kodwa futhi ube nomthelela obalulekile ekugcwalisweni kwe-saturation kanye nokushuba kokuqhekeka kokuqhekeka kwe-matrix.Isibonelo, kuma-orthogonal laminates, kukhona ubudlelwano obuhambelanayo phakathi kokuqina kokuphuka kanye nezinga lokukhula kwe-crack ngaphansi komthwalo ofanayo wangaphandle.Ngakho-ke, ochwepheshe kudingeka banqume isiqondiso nokuhleleka kokuhlelwa kwe-prepreg ngokuvumelana nezidingo zeshidi lamandla aqinile, amandla okugunda kanye namandla.Nikeza umdlalo ogcwele izinzuzo ze-carbon fibre composite materials.

Isiqondiso sokubeka i-prepreg kufanele sibekwe ngokuvumelana nesiqondiso esiyinhloko somthwalo.Isiqondiso sokubeka sihlanganisa u-0°, ±45°, no-90°.Esimeni sokucindezeleka kwe-shear, ungqimba olune-engeli engu-0 ° luhambisana nokucindezeleka okuvamile, ungqimba olune-engeli engu-±45 ° luhambisana nokucindezeleka kokugunda, futhi ungqimba olune-angle engu-90 ° lusetshenziselwa ukuqinisekisa ukuthi umkhiqizo we-carbon fiber unengcindezi eyanele eyanele ekuqondeni kwe-radial.Ngokusho kwabasebenzi baseBoshi, uma umthwalo webhodi le-carbon fiber ngokuyinhloko ucindezela futhi ucindezela umthwalo, khona-ke isiqondiso se-layup kufanele sibe isiqondiso somthwalo wokucindezela nokucindezela;uma umthwalo webhodi le-carbon fiber ngokuyinhloko umthwalo we-shear, khona-ke i-layup Phakathi, ngokuyinhloko ukubeka ngamabili we-± 45 °;uma umthwalo webhodi le-carbon fiber uyinkimbinkimbi futhi uhlanganisa imithwalo eminingi, khona-ke umklamo wokugandaya kufanele uxutshwe ngezindlela eziningi ze-0 °, ± 45 °, no-90 °.

3. Ukwelashwa kwangaphambi kokukhulelwa:

Ngemuva kokuthi i-carbon fiber prepreg isikiwe futhi ibekwe ngendlela ehlelekile, izongena kunqubo yokushisa nokucindezela.I-prepreg laminated ifakwe esikhunjini esinezinga lokushisa elibekiwe futhi sishise futhi sicindezeleke.Isikhunta sivaliwe.Izinto ezenziwe nge-laminated kancane kancane ziqina ngaphansi kwengcindezi eshisayo futhi zifinyelele izinga elithile lokuqiniswa.Isikhunta siyavuleka bese sidonswa idivayisi yokudonsa.Cindezela isikhunta ukuze uqedele ukwelapha.

Phakathi nayo yonke inqubo yokuphulukisa, isikhathi sokushisa nokucindezela sidinga ukulungiswa ngokuvumelana nezidingo ezahlukene zebhodi le-carbon fiber.Amazinga okushisa ahlukene nesikhathi sokushisa kuzoba nomthelela ezintweni ezibonakalayo zamashidi we-carbon fiber.Enqubweni yangempela yokukhiqiza, isikhathi sesiteji sokucindezela okushisayo kufanele sifinyezwe ngangokunokwenzeka ngaphansi kwesisekelo sokugcina ukuzinza kwe-dimensional ngesikhathi sesigaba sokuphulukisa sengxenye.

Ibhodi le-carbon fiber ekhiqizwa yi-Jiangsu Boshi Carbon Fiber ingakhetha inqubo yokukhiqiza efanele ngokuvumelana nezidingo zobuchwepheshe zekhasimende ukuze kuqinisekiswe ukuzinza komkhiqizo, ukwelashwa kwendawo, ukubekezelela ukushuba, njll., kanye nekhwalithi yomkhiqizo ingaqinisekiswa ngempumelelo.

4. Ngemuva kokucubungula amapuleti:

Ngemuva kokuthi ibhodi le-carbon fiber liqiniswe futhi lakhiwe, ukusika, ukubhoboza nokunye ukucubungula kuyadingeka ngezidingo zokunemba noma izidingo zomhlangano.Ngaphansi kwezimo ezifanayo zokusika imingcele yenqubo, ukujula kokusika, njll., umphumela wokukhetha amathuluzi nama-drill wezinto ezihlukahlukene, ubukhulu, nokubunjwa kuhluke kakhulu.Ngesikhathi esifanayo, izici ezifana namandla, isiqondiso, isikhathi kanye nezinga lokushisa lamathuluzi nama-drill nakho Kuzothinta umphumela wokucubungula.

Isikhathi sokuthumela: Sep-23-2021